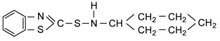

Products

Rubber vulcanization accelerator CBS (CZ)

Video

Specification

|

Item |

Index |

||

|

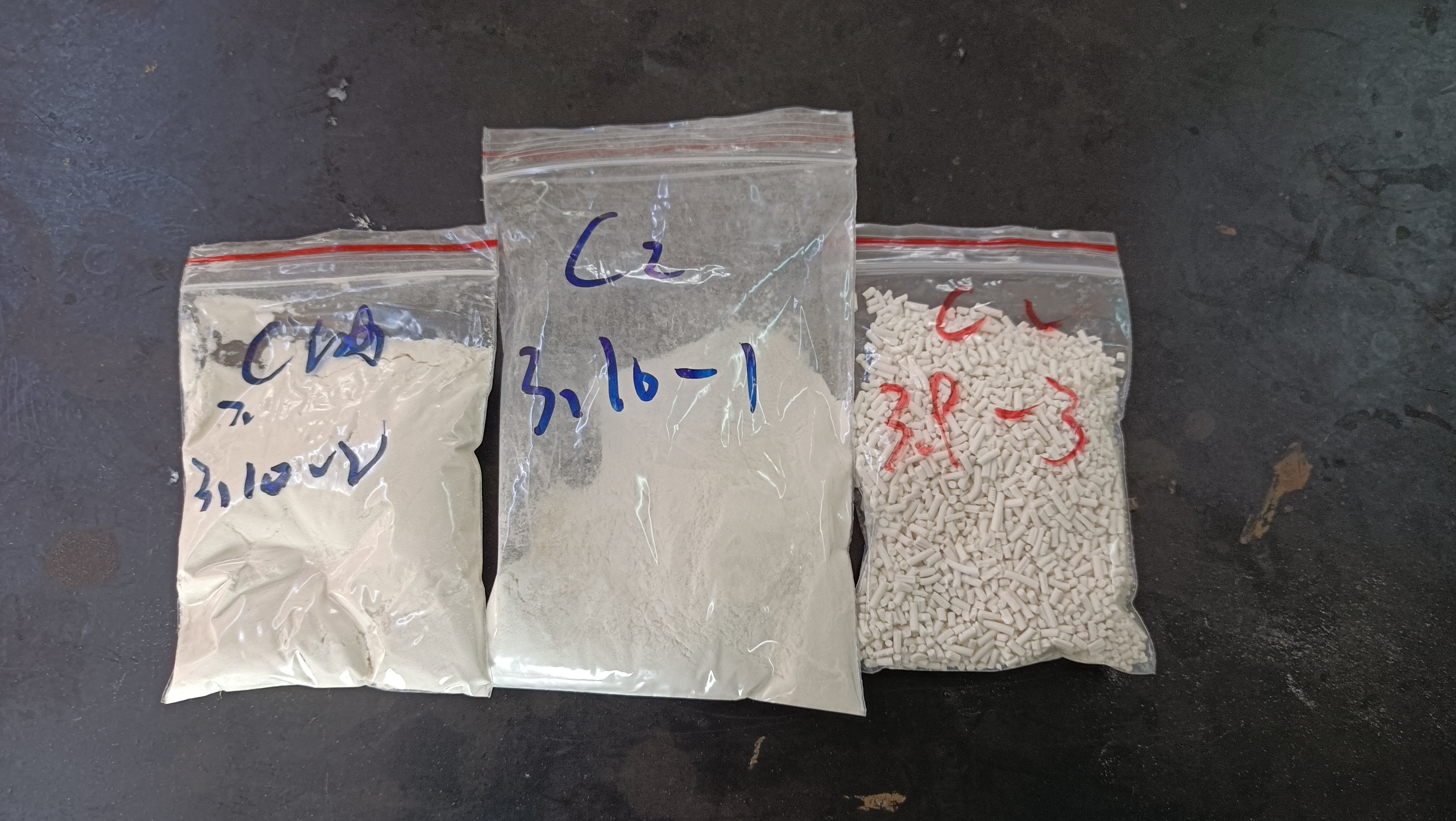

Type |

Powder |

Oiled Powder |

Granular |

|

Appearance |

Grayish-white or light yellow powder or granule |

||

|

Melting Point |

Min 98℃ |

Min 97℃ |

Min 97℃ |

|

Heat Loss |

Max 0.4% |

Max 0.5% |

Max 0.4% |

|

Ash |

Max 0.3% |

Max 0.3% |

Max 0.3% |

|

Residues On 150μm Sieve |

Max 0.1% |

Max 0.1% |

---- |

|

In soluble In Methanol |

Max 0.5% |

Max 0.5% |

Max 0.5% |

|

Free Amine |

Min 0.5% |

Min 0.5% |

Min 0.5% |

|

Purity |

Min 96.5% |

Min 95% |

Min 96% |

|

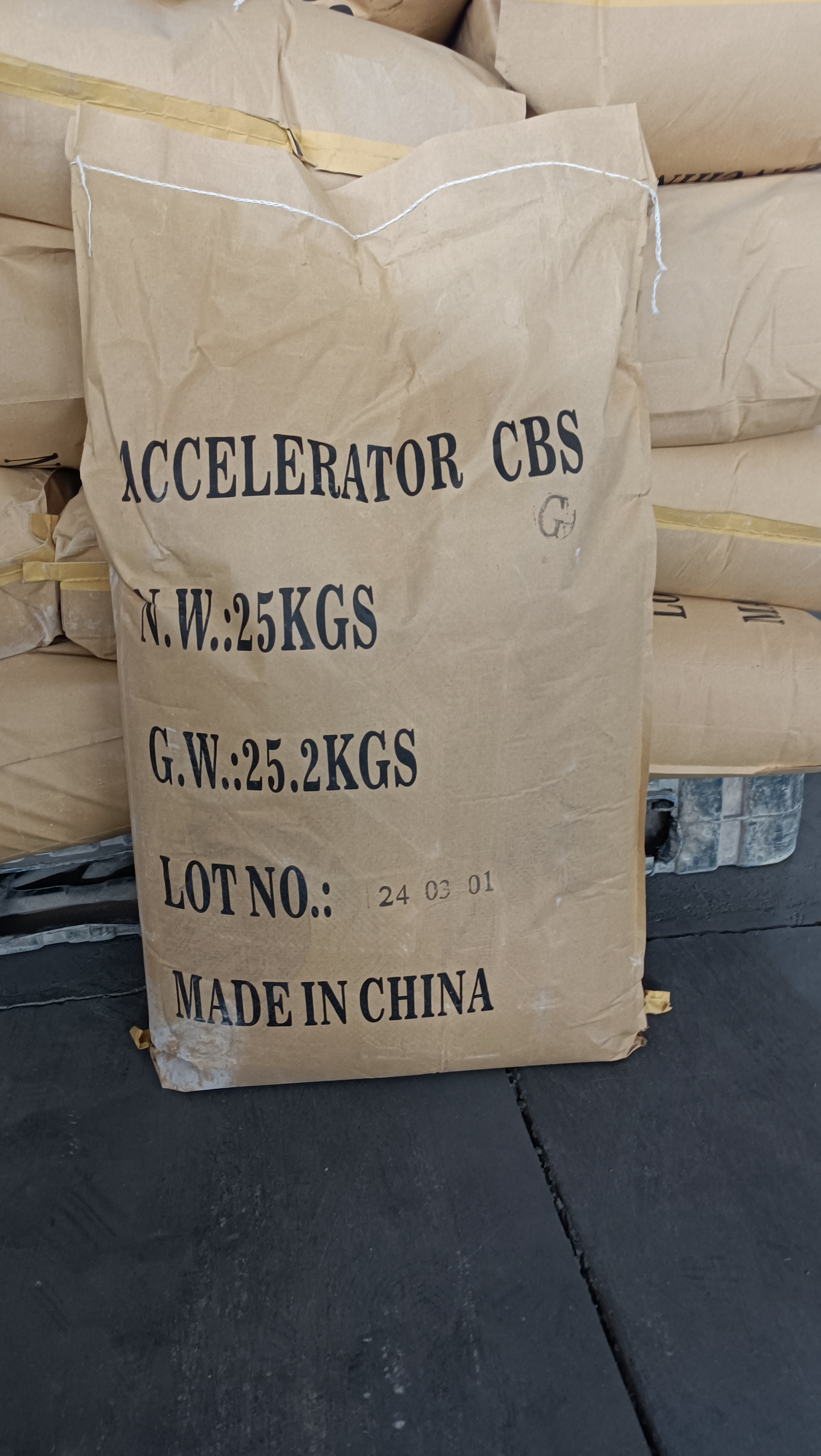

Packaging |

25 Kg/Bag |

||

Application

Rubber vulcanization is mainly carried out using sulfur, but the reaction between sulfur and rubber is very slow, so vulcanization accelerators have emerged. Adding an accelerator to the rubber material can activate the vulcanizing agent, thereby accelerating the cross-linking reaction between the vulcanizing agent and rubber molecules, achieving the effect of shortening vulcanization time and reducing vulcanization temperature.The promotion efficiency of rubber vulcanization is an important standard for measuring the quality of accelerators. From the reports, the characterization of accelerators at home and abroad mainly focuses on two aspects: the vulcanization promotion characteristics and the physical and mechanical properties of vulcanizate. The vulcanization promotion characteristics mainly examine aspects such as vulcanization rate, Mooney scorch time, positive vulcanization time, positive vulcanization temperature, vulcanization flatness during the over vulcanization stage, and resistance to vulcanization reversion.One of the commonly used aftereffect accelerators.Suitable for the use of furnace black rubber, mainly used in tires, rubber shoes, rubber hose, tape, cable, general industrial products.

Packing

25 kgs / bag, plastic woven bag lined with PE bag, paper plastic composite bag and kraft paper bag.

Product Picture

Storage

Keep container tightly closed in a cool, well-ventilated place. Recommended max. Under normal conditions, the storage period is 2 years.

Note: This product can be made into ultra-fine powder according to customer requirements.