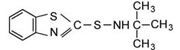

Alaabta

TBBS (NS) dardargeliyaha vulcanization-ka caagga ah

Tilmaamid

| Shayga | Tusmada |

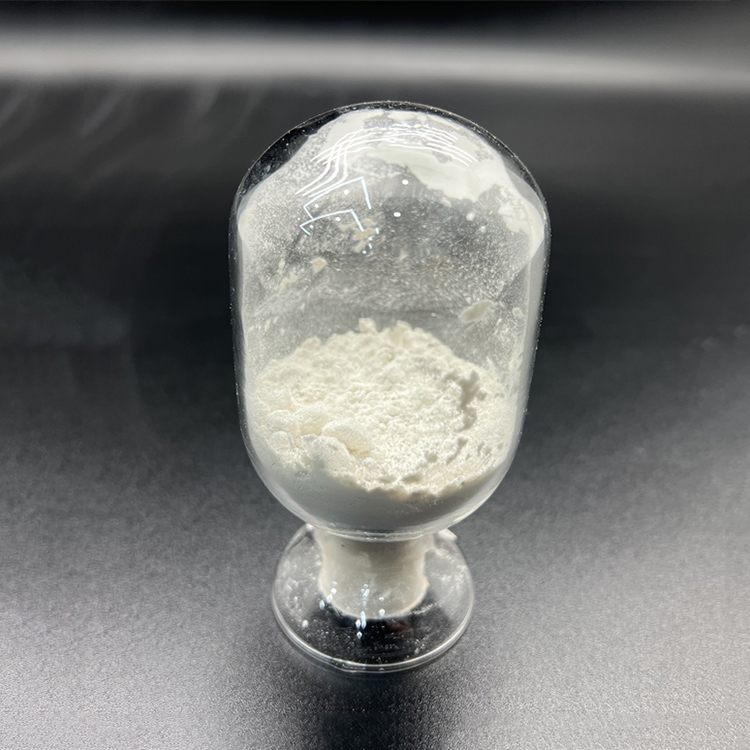

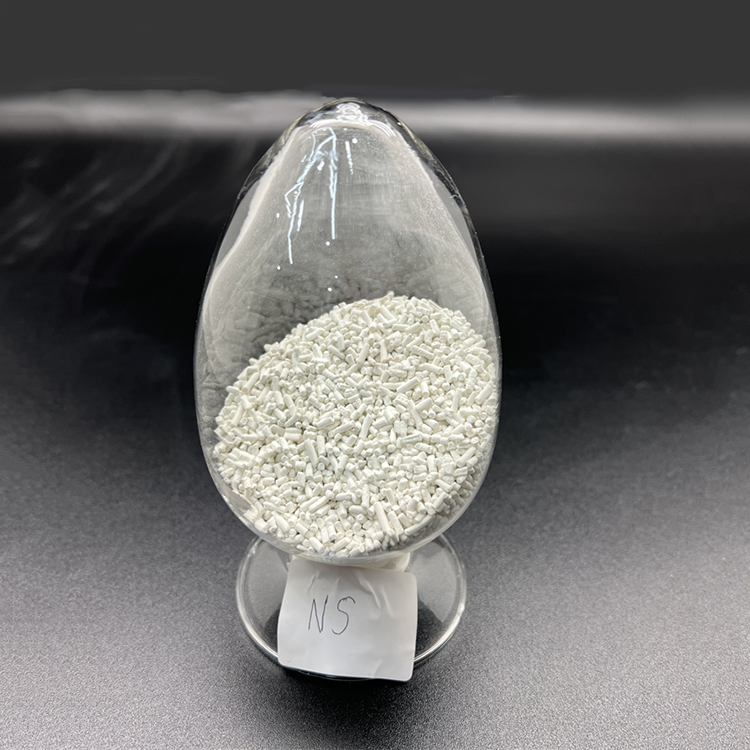

| Muuqashada | Caddaan ama budo huruud ah ama granular |

| Xildhibaanka hore ≥ | 104℃ |

| Khasaaraha qalajinta ≤ | 0.4% |

| Ash ≤ | 0.3% |

| Hadhaaga 150 μm shaandho ≤ | 0.1% |

| Aan lagu milmi karin Methanol ≤ | 1% |

| Aamin bilaash ah ≤ | 0.5% |

| daahirnimo ≥ | 96% |

NS waxa kale oo loo yaqaanaa:n-tert-butyl-2-benzothiazolesulphenamide;dardar-geliyaha ns;2- (tert-butylaminothio) benzothiazole;n-tertiarybutyl-2-benzothiazole sulfennamide;tbbs;2-[(tert-butylamino)sulfanyl]-1,3-benzothiazole;2-benzothiazolesulfenamide, n-tert-butyl-;accel bns;acelbns;dardargeliyaha(ns);dardar-geliyayaasha;akrochem bbts.

Astaamaha Isticmaalka Application

Dardariyeyaasha dib u dhigay ee caag dabiici ah, caag synthetic ah, iyo caag dib loo warshadeeyay.Badbaadada wanaagsan heerkulka shaqada.Alaabtani waxay si gaar ah ugu habboon tahay habka foornada saliidda alkaline ee alaabta caag madow ee kaarboon, maadaama ay sababi karto isbeddel midab iyo wasakh yar oo ah alaabta caagga ah.Inta badan waxaa loo isticmaalaa taayirka, tuubada, cajaladaha, kabaha caagga ah, fiilada, warshadaha taayirada, iyo sidoo kale alaabada caagga ah.Alaabtani waxay u baahan tahay isticmaalka zinc oxide iyo stearic acid, waxaana sidoo kale lagu hawlgelin karaa thiurams, dithiocarbamates, aldehydes, dardaryaasha guanidine, iyo walxaha acidic.Qiyaasta guud ahaan waa 0.5-1.5 qaybood, waxayna ku beddeli kartaa NOBS qadar yar oo ah wakiilka ka hortagga coking-ka ee CTP.

Ka taxadaritaan

Ka fogow taabashada maqaarka iyo indhaha.

Codsiga

Alaabtani waa dhiirigeliyaha saameynta dambe ee caagga dabiiciga ah, cis-1, 4-polybutadiene caag, caag isoprene, caag butadiene styrene, iyo caag dib loo warshadeeyay, gaar ahaan ku habboon qalabka caag madow ee carbon leh alkalinity xooggan.Badbaadada heerkulka shaqaynta, iska caabin gubasho xoog leh, xawaaraha vulcanization degdeg ah, xoog dhererka sare, oo kordhin kara saamiga caag synthetic ee la isticmaalo.Sunta hoose iyo hufnaanta sare, waa beddelka ugu habboon ee NOBS, oo leh waxqabad dhammaystiran oo heersare ah, waxaana loo yaqaannaa dardar-geliyaha caadiga ah.Si ballaaran loo isticmaalo soo saarista taayirada radial.Waxaa lagu dari karaa aldehydes, guanidine, iyo thiuram accelerators, iyo sidoo kale wakiilka ka hortagga coking PVI, si loo sameeyo nidaam vulcanization wanaagsan.Inta badan loo isticmaalo soo saarista iyo soo saarista taayirrada, kabaha caagga ah, tuubooyinka caagga ah, cajalad, iyo fiilooyinka.Ka sokow, waqtiga daawaynta waa gaaban yahay, caabbinta guban iyo badbaadada habaysan wanaagsan.Si ballaaran loo isticmaalo dhammaan noocyada alaabta caagga ah iyo taayirada, gaar ahaan farsamaynta taayirada radial.Iyada oo leh faa'iidooyinka xawaaraha saamaynta ka dib.

Baakad

25kg bac caag ah, bac-cag ah oo isku dhafan, bac warqad kraft ama bac jumbo ah.

Sawirka Alaabta

Kaydinta

Weelka si adag u xidh meel qabow oo hawo fiican leh.lagu taliyay max.Xaaladaha caadiga ah, muddada kaydinta waa 2 sano.

Fiiro gaar ah: Alaabtan waxaa laga dhigi karaa budo aad u fiican sida waafaqsan shuruudaha macaamiisha.