Imikhiqizo

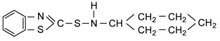

I-Rubber vulcanization accelerator CBS (CZ)

Ukucaciswa

| Into | Inkomba | ||

| Uhlobo | Impushana | I-Oiled Powder | I-Granular |

| Ukubukeka | Impushana empunga-emhlophe noma ephuzi ngokukhanyayo noma imbudumbudu | ||

| I-Melting Point | Ubuncane 98℃ | Ubuncane 97℃ | Ubuncane 97℃ |

| Ukulahlekelwa Ukushisa | Ubukhulu 0.4% | Ubukhulu 0.5% | Ubukhulu 0.4% |

| Umlotha | Ubukhulu 0.3% | Ubukhulu 0.3% | Ubukhulu 0.3% |

| Izinsalela Ku-150μm Sieve | Ubukhulu 0.1% | Ubukhulu 0.1% | ---- |

| Encibilikayo Ku-Methanol | Ubukhulu 0.5% | Ubukhulu 0.5% | Ubukhulu 0.5% |

| Mahhala | Ubuncane 0.5% | Ubuncane 0.5% | Ubuncane 0.5% |

| Ubumsulwa | Ubuncane 96.5% | Ubuncane 95% | Ubuncane 96% |

| Ukupakisha | 25Kg/Isikhwama | ||

Isicelo

I-vulcanization ye-Rubber yenziwa ikakhulukazi kusetshenziswa isibabule, kodwa ukusabela phakathi kwesibabule nenjoloba kuhamba kancane, ngakho-ke ama-accelerators we-vulcanization avele.Ukwengeza i-accelerator kokokusebenza kwenjoloba kungenza kusebenze i-ejenti elimazayo, ngaleyo ndlela kusheshise ukusabela okuxhumanisa phakathi kwe-ejenti elimazayo nama-molecule enjoloba, kuzuzwe umphumela wokunciphisa isikhathi se-vulcanization kanye nokunciphisa izinga lokushisa le-vulcanization. yokukala ikhwalithi yama-accelerator.Kusukela emibikweni, ukucaciswa kwama-accelerator ekhaya nakwamanye amazwe ikakhulukazi kugxile ezicini ezimbili: izici zokuthuthukisa i-vulcanization kanye nezakhiwo zomzimba nezomshini ze-vulcanizate.Izici zokuthuthukisa i-vulcanization ikakhulukazi zihlola izici ezifana nesilinganiso sokuvuvukala, isikhathi sokushiswa kwe-Mooney, isikhathi esivumayo sokuvuvukala, izinga lokushisa elilungile le-vulcanization, i-vulcanization flatness ngesikhathi sesigaba se-vulcanization, kanye nokumelana nokuhlehliswa kwe-vulcanization.Enye yezisheshisi ezivame ukusetshenziswa ngemuva komphumela. wenjoloba emnyama yesithando somlilo, esetshenziswa kakhulu kumathayi, izicathulo zenjoloba, ipayipi lenjoloba, itheyiphu, ikhebula, imikhiqizo yezimboni ejwayelekile.

Ukupakisha

25 kgs / isikhwama, isikhwama sepulasitiki esilukiwe esifakwe isikhwama se-PE, isikhwama sepulasitiki esiyinhlanganisela yephepha kanye nesikhwama sephepha se-kraft.

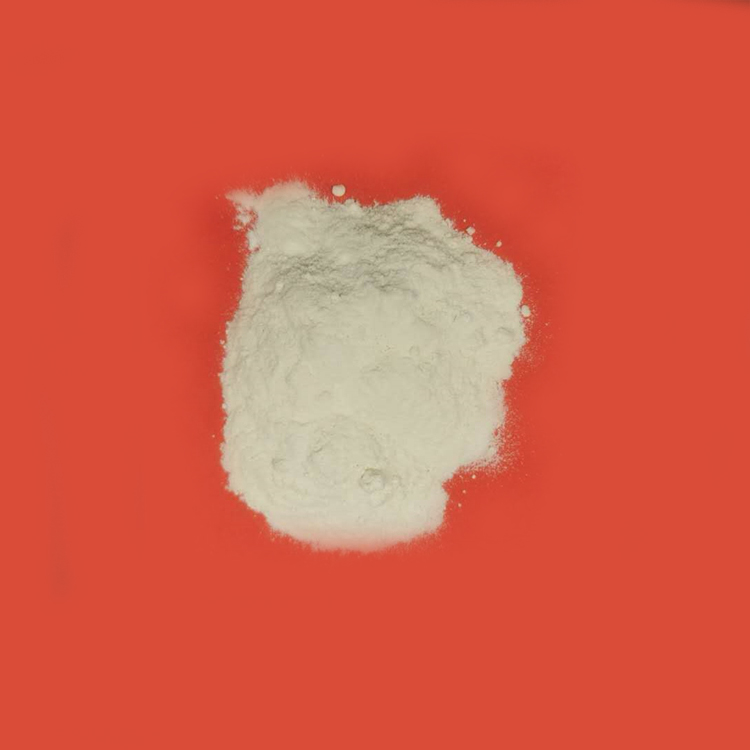

Isithombe somkhiqizo

Isitoreji

Gcina isitsha sivalwe ngokuqinile endaweni epholile, enomoya omuhle.Ubukhulu obunconyiwe.Ngaphansi kwezimo ezijwayelekile, isikhathi sokugcina siyiminyaka emi-2.

Qaphela: Lo mkhiqizo ungenziwa ube i-ultra-fine powder ngokwezidingo zekhasimende.